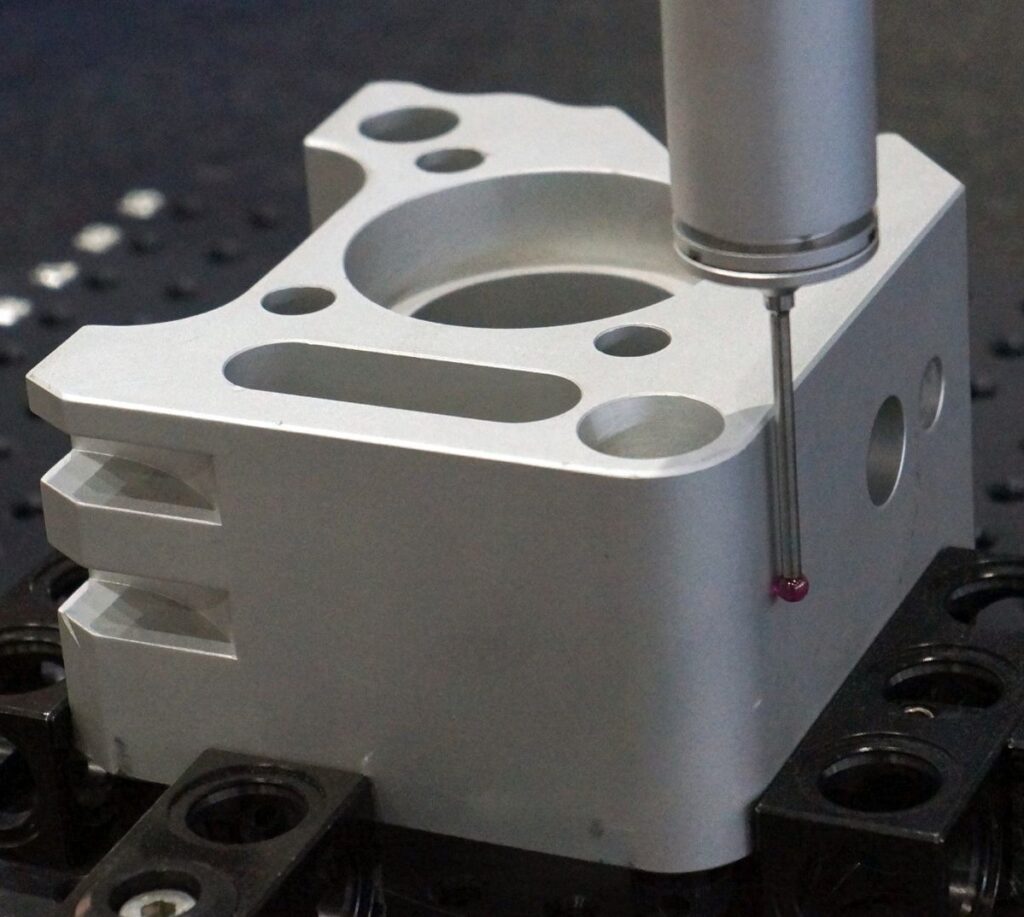

Cloudwave Technologies is a leading provider of precision machined and sheetmetal parts.

We cater to diverse industries such as Semiconductor, Electronics, Aerospace, Telecom, Energy, Medical, and Automotive. Our strong focus on delivering high-quality products ensures that our lightweight sheetmetal and machined components meet the highest industry standards.

Whether you need fully finished kits ready for integration or individual precision parts, we are your trusted partner. Our goal is to empower your business with innovative, high-quality solutions that not only meet but exceed your expectations. Choose Cloudwave for precision, reliability, and optimal performance in your projects.

“Precision Matchmaking”, finding your ideal supplier.

- ISO 9001:2015 Certified Excellence

- Personalized Support, Prompt Response

- Unbeatable Competitive Edge

- All-Inclusive Capabilities, Streamlined Efficiency

- Expertise and Speed in Manufacturing

We're Thriving and Building Better Products

Testimonials

Our seamless journey from prototyping to production empowers us to deliver advanced manufacturing solutions tailored to your requirements.

"Cloudwave precision and attention to detail in every project showcased their expertise. We were impressed by their ability to deliver high-quality products within tight deadlines, making them a reliable partner for our manufacturing needs."

"Cloudwave skilled team utilized state-of-the-art technology to fabricate intricate designs with utmost accuracy. Their dedication to understanding our requirements and delivering flawless results sets them apart in the industry."

"Choosing Cloudwave for our sheet metal and machining requirements was a game-changer. With their top- notch machinery, they consistently delivered outputs that met our specifications, making them an indispensable asset for our manufacturing projects"